Products

-

1600MM SMS non woven fabric production line

This equipment is suitable for the production of spunbond nonwovens with a variety of colors and different properties using PP chips as main material mixed with master batch, anti-oxygen, anti-pilling agent and flame retardant. This machine can produce four-layer SMS nonwovens as well as two-layer SS nonwovens.

-

PS fast food box line

This production line adopts double-screw foam sheet extrusion technology. PSP foam sheet is a kind of new-type packing material with the features of heat preservation, safety, sanitation and good plasticity. It’s mainly used to make various types of food containers, such as lunch box, dinner trays, bowls etc by thermoforming. It’s also can be used to make advertisement board, industrial products packing and so on. It has stable performance, big capacity, high automation and yields quality products.

-

6 color flexo printing machine

This machine uses AC main motor synchronous belt drive each printing group of high-precision planetary gearbox (360° plate) gear transmission die-over roller (can be positive and negative printing conversion)

-

S non woven fabric production line

1. Raw material index

MFJ) 30~35g/10min

MFJ Deviation max±1

Melting point 162~165℃

Mw/Mn) max<4

Ash content ≤1%

Water content <0.1%

2. Material consume:0.01 -

4 color paper printing machine

1. Main motor frequency control,power

2. PLC touch screen control the whole machine

3. Reduce motor separate -

High speed square bottom paper bag machine

This machine is used for roll primary color paper or printing roll paper such as kraft paper. Paper rolls such as food paper are completed by this machine at one time. Automatic center gluing, raw material into tube, cut to length, bottom indentation, bottom folding. Glue on the bottom and shape the bottom of the bag. Finished bag finishing is completed at one time. This machine is more convenient to operate, more efficient and more stable. It is an environmentally friendly paper bag machine equipment that produces various paper bags, snack food bags, bread bags, dried fruit bags, etc.

-

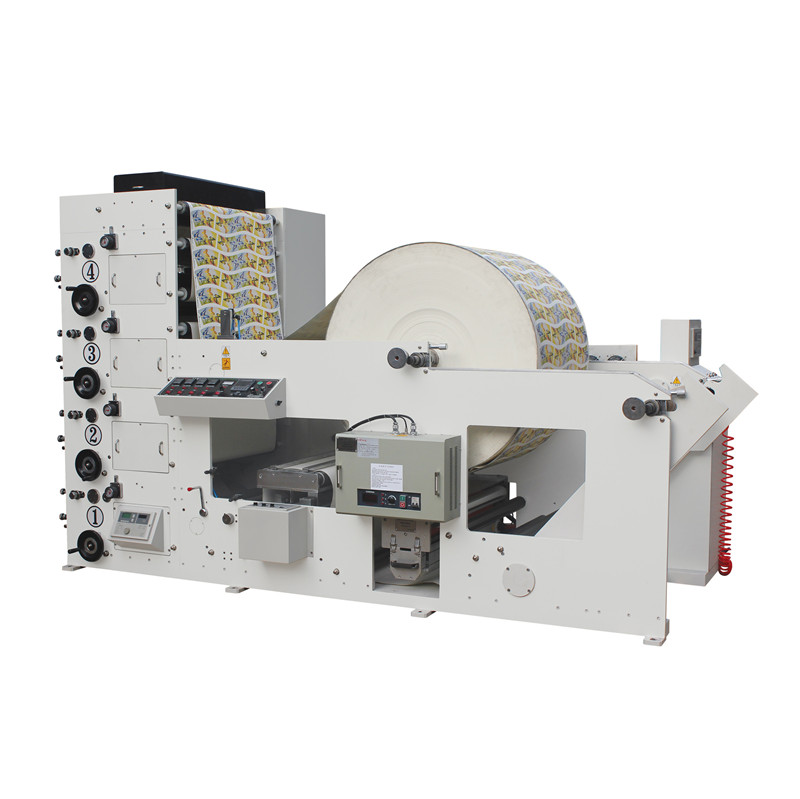

4 Colors flexo printing machine

Max web width:1020mm

Max printing width:1000mm

Printing Circumference:317.5~952.5mm

Max unwinding diameter:1400mm

Max rewinding diameter:1400mm

Register precision:±0.1mm

Printing Gear:1/8cp

Working speed:150m/min -

6 color film printing machine

1. The machine adopt with synchronous belt drive and hard gear face gear box. The gear box adopt with synchronous belt drive each printing group high precision planetary gear oven(360º adjust the plate)

gear driving the press printing roller(can print two sides conversion).

2. After printing, long running material space ,it can make the ink drying easily,better results. -

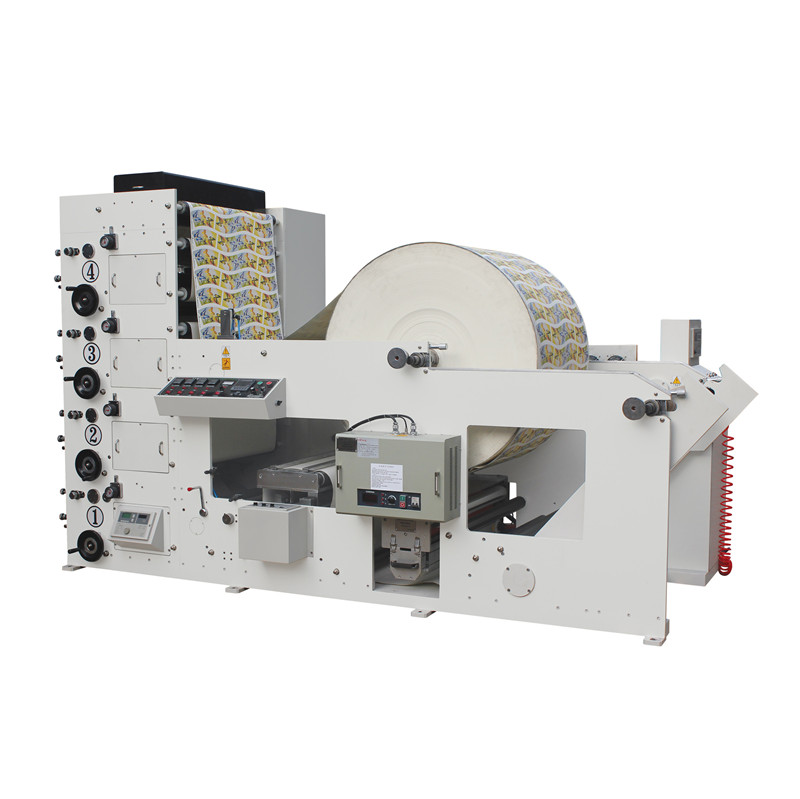

4 color Paper Cup Printing Machine

Max Web Width:950mm

Max Printing Width:920mm

Printing Circumference:254~508mm

Max Unwinding Diameter:1400mm

Max Rewinding Diameter:1400mm

Printing Gear:1/8cp

Max Printing Speed:100m/min(It depends on such as paper ,ink and other factors)Plate Thickness:1.7mm

Paste Version Tape Thickness:0.38mm -

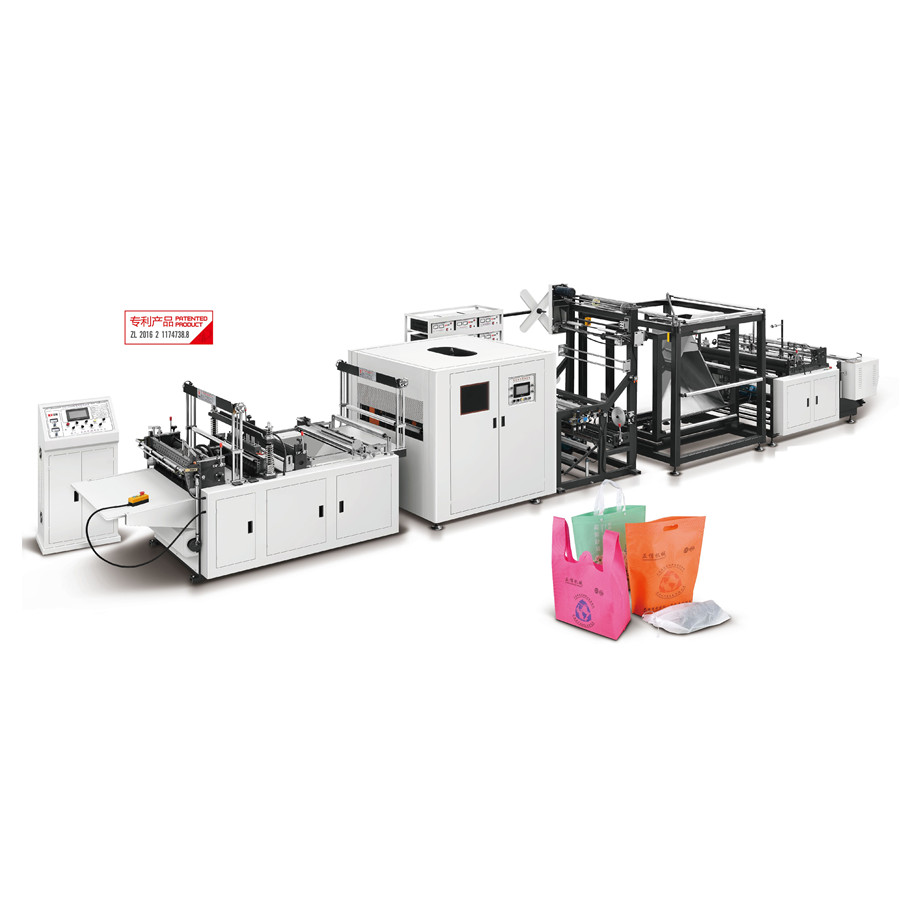

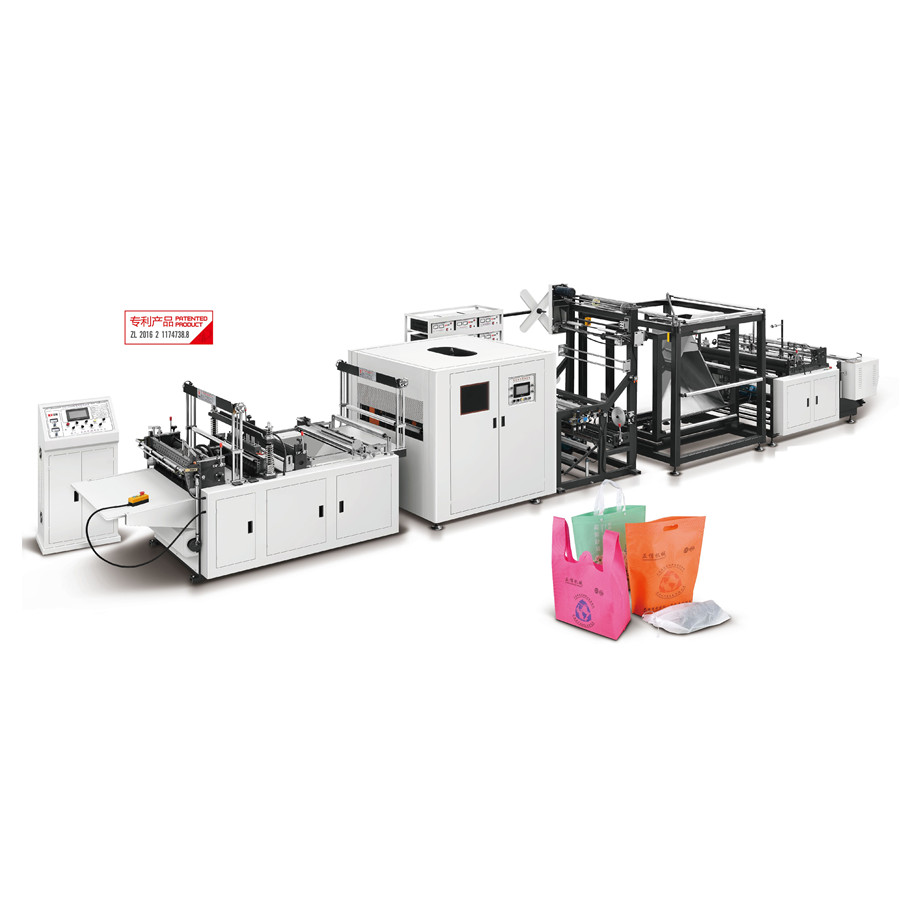

Non-woven Laminated Box Bag Making Leader Machine

Model: ZX-LT500

Non-woven Laminated Box Bag Making Leader Machine

This machine adopts mechanical, optical, electrical and pneumatic integration technology, suitable for feeding the roll material of non-woven fabric and laminated non-woven fabric. It’s a specialized equipment for making the primary shaping non-woven(laminated) three dimensional bag(no need to turn the bag inside out). This equipment features stable production, strong and decent sealing of bags, good looking, top grade, fancy and reusable, mainly applied in the field of non-woven wine packing, beverage packing, gift bags and hotel promotional bags etc. -

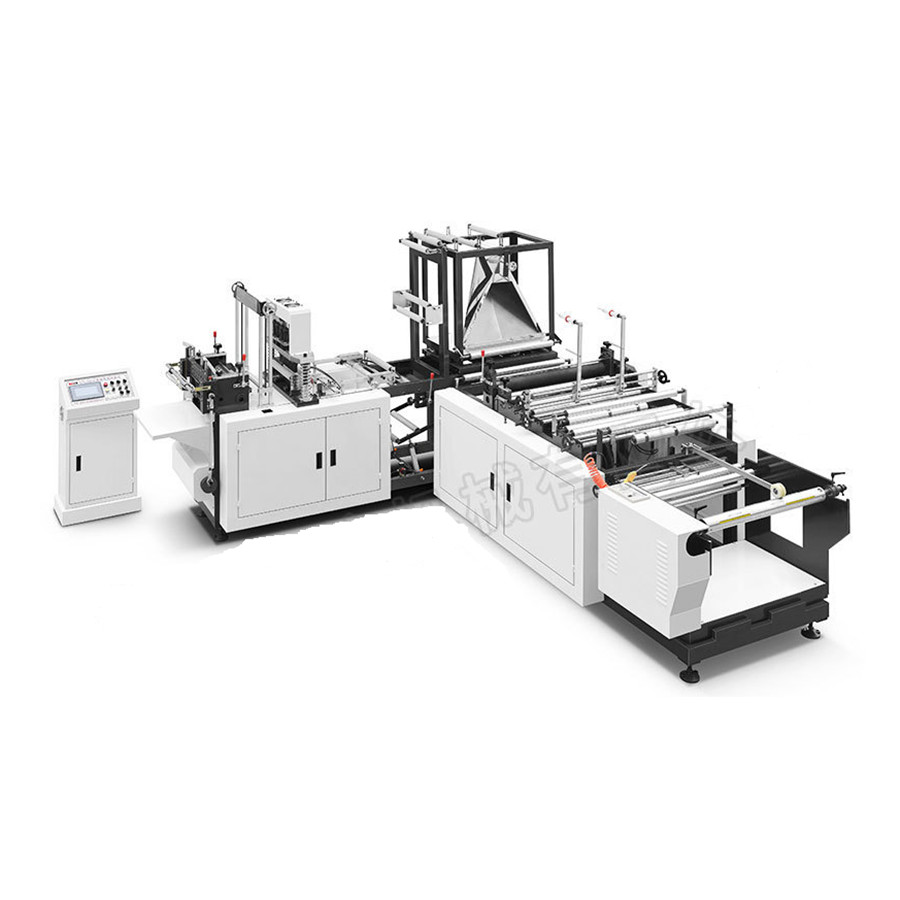

Non-woven Bag Making Machine (6-in-1)

This machine adopts mechanical, electrical, optical and pneumatic integration technology, It’s a advanced equipment and has the function of automatic handle loop bonding.

-

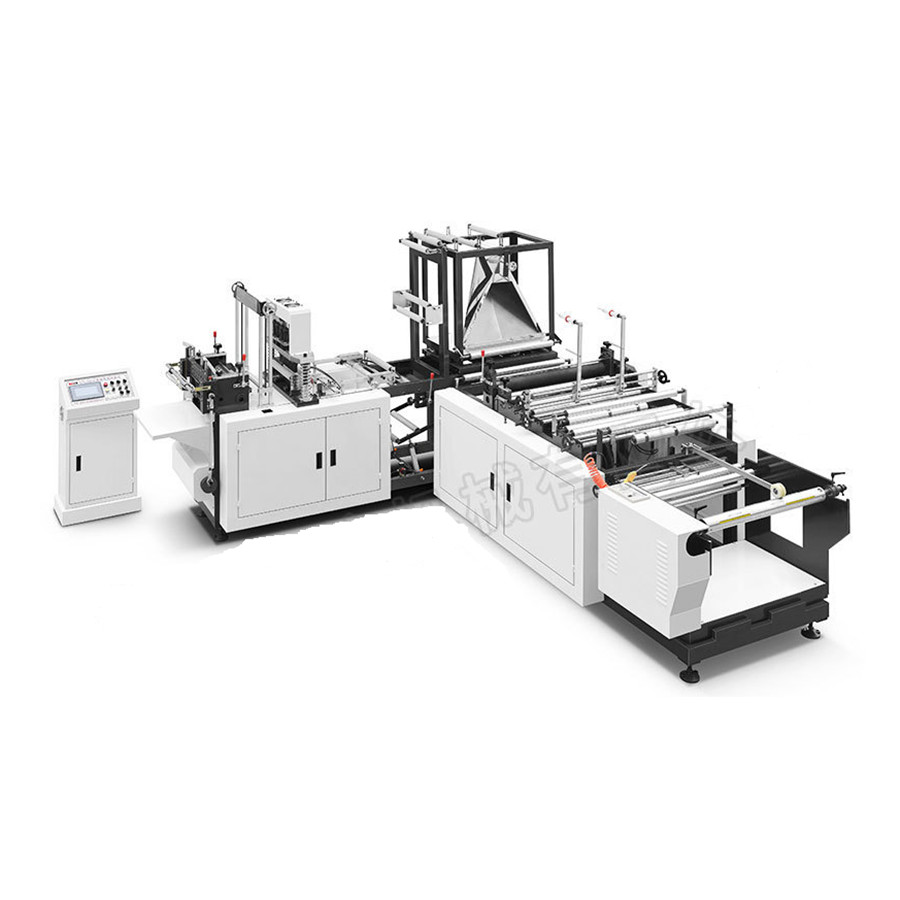

Multifunctional Non-woven Flat Bag Making Machine

This machine adopts mechanical, electrical, optical and pneumatic integration technology, suitable for non-woven fabric, different specs of non woven bags can be made by this machine.