Printing Shop Machines Supplier – 6 color film printing machine – MACHINERY

Printing Shop Machines Supplier – 6 color film printing machine – MACHINERY Detail:

CONTROL PART

1.Double work station.

2.3 inch air shaft.

3.Magnetic powder brake auto tension control.

4.Auto web guide.

UNWINDING PART

1.Double work station.

2.3 inch air shaft.

3.Magnetic powder brake auto tension control.

4.Auto web guide

PRINTING PART

1. Pneumatic lifting and lowing printing plate cylinders auto lifting plate

cylinder when the machine is stopped. After that can run ink automatically.

When the machine is opening,it will make alarm to start the auto lowering

plate printing cylinder.

2. Inking with ceramic anilox with chambered doctor blade (6 pcs).

3. High precision planetary gear oven 360°circulation longitudinal register.

4. ±0.2mm transverse register.

5. Adjust inking press and printing pressure press by manual.

6. Can print 6+0, 5+1, 4+2, 3+3

| MODEL | GT6-800 | GT-1000 |

| Max. Printing material width | 800mm | 1000 |

| Max. Printing width | 760mm | 960mm |

| Max. Unwinding diameter | 600mm | 600mm |

| Max. Rewinding diameter | 600mm | 600mm |

| Printing length range | 230-1000mm | 230-1000mm |

| Printing speed | 5-100m∕min | 5-100m/min |

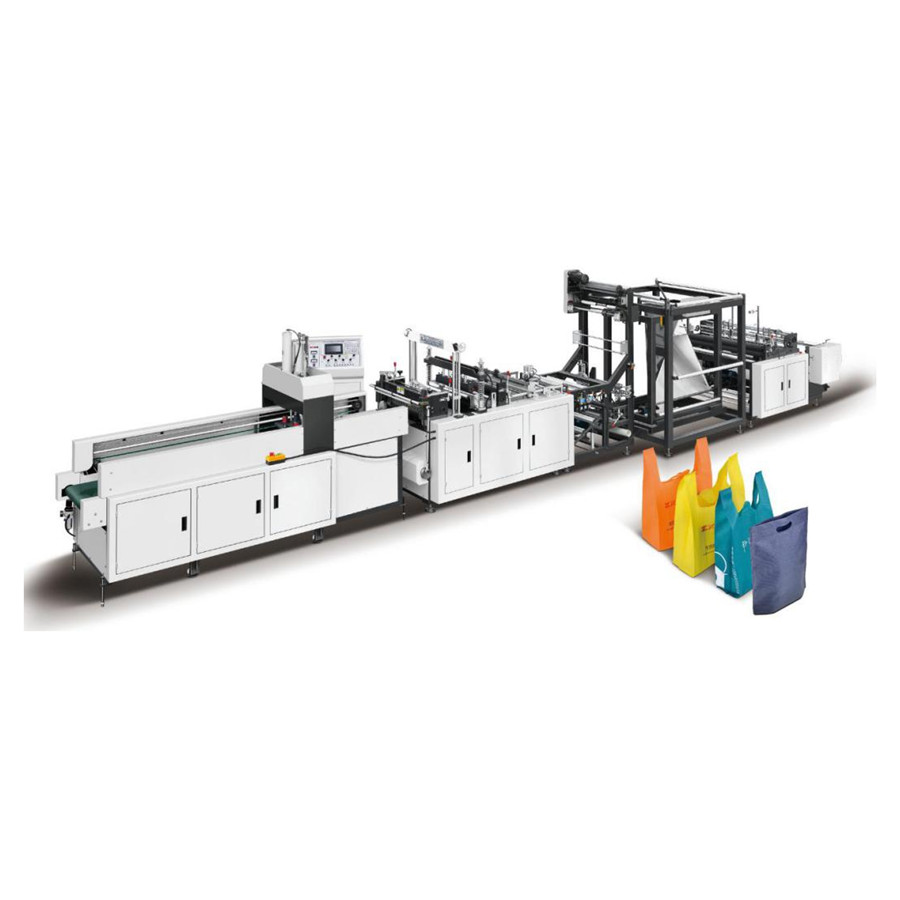

Product detail pictures:

Related Product Guide:

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for Printing Shop Machines Supplier – 6 color film printing machine – MACHINERY , The product will supply to all over the world, such as: Sevilla, Toronto, Venezuela, Relying on superior quality and excellent post-sales, our products sell well in America, Europe, the Middle East and South Africa. We are also the appointed OEM factory for several worlds' famous products brands. Welcome to contact us for further negotiation and cooperation.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

Write your message here and send it to us