Melt Blown Fabric Meltblown Nonwoven Factory – Semi-auto Single Side Handle Attaching Machine – MACHINERY

Melt Blown Fabric Meltblown Nonwoven Factory – Semi-auto Single Side Handle Attaching Machine – MACHINERY Detail:

Main technical parameters:

| Model |

LH-U700 |

| Handle Loop Length |

380-600mm |

| Material Basis weight(thickness) |

40-100g/m² |

| Production Speed | 5-20pcs/min |

| Power Supply |

220V50HZ |

| Total Power |

5kw |

| Overall Dimension |

2100*1200*1500mm |

| Weight |

450KG |

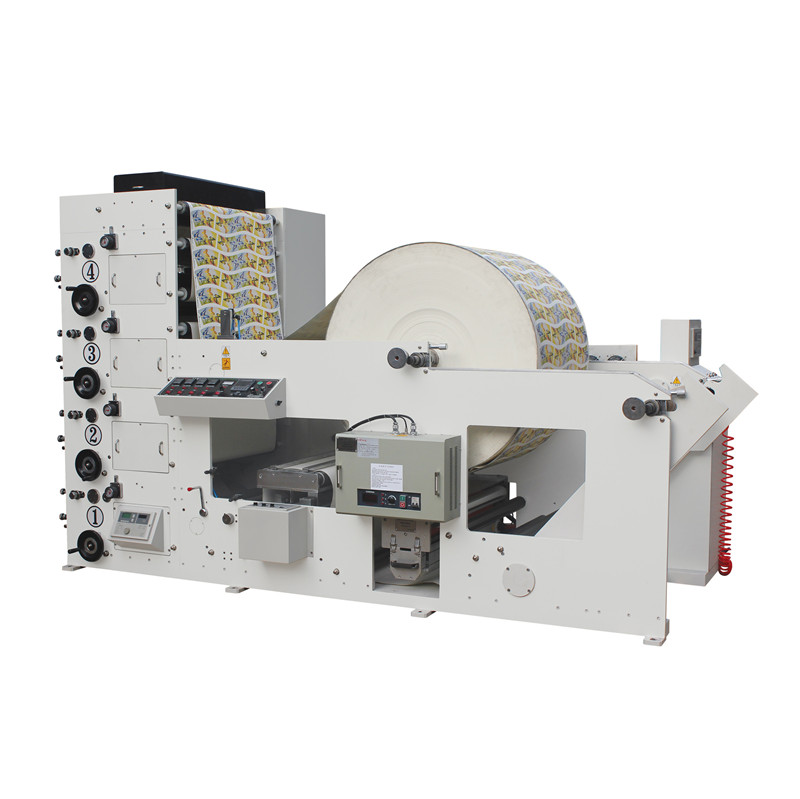

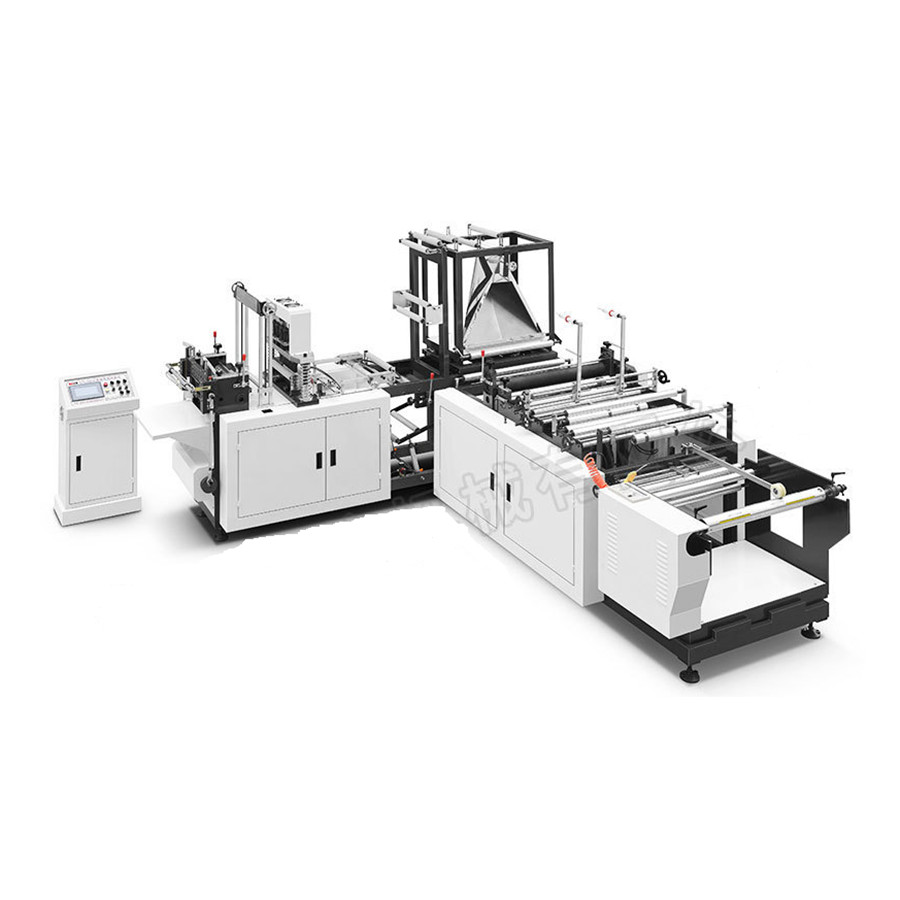

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for Melt Blown Fabric Meltblown Nonwoven Factory – Semi-auto Single Side Handle Attaching Machine – MACHINERY , The product will supply to all over the world, such as: Korea, Sierra Leone, Israel, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

Write your message here and send it to us