China High Quality Small Melt Blown Machine – S non woven fabric production line – MACHINERY

China High Quality Small Melt Blown Machine – S non woven fabric production line – MACHINERY Detail:

C. Public project

1. Water supplication

Pressure 2-4Bar

Temperature ≤28℃ PH : 6.5~9.2 Turbidity <10PPm

2. Compressed air

Operation pressure : 4-6Bar Allow range : ±0.2Bar

Dew point temperature :<25℃ Prevision : 1m3

A. Characteristics

| model no | 1600MM S | 2400MM S | 3200MM S |

| Capacity | 4-6 T/ DAY | 5-7 T/DAY | 8-10 T/DAY |

| Voltage | 240V OR 415V/50HZ | 240V OR 415V/50HZ | 240VOR 415V/50HZ |

| Installed power | 350 kw | 400kw | 500kw |

| Running power | 300 kw | 360 kw | 480 kw |

| effective width | 1600MM | 2400MM | 3200MM |

| Motor | Siemens | Siemens | Siemens |

| PLC | Siemens | Siemens | Siemens |

| Drive | Japan | Japan | Japan |

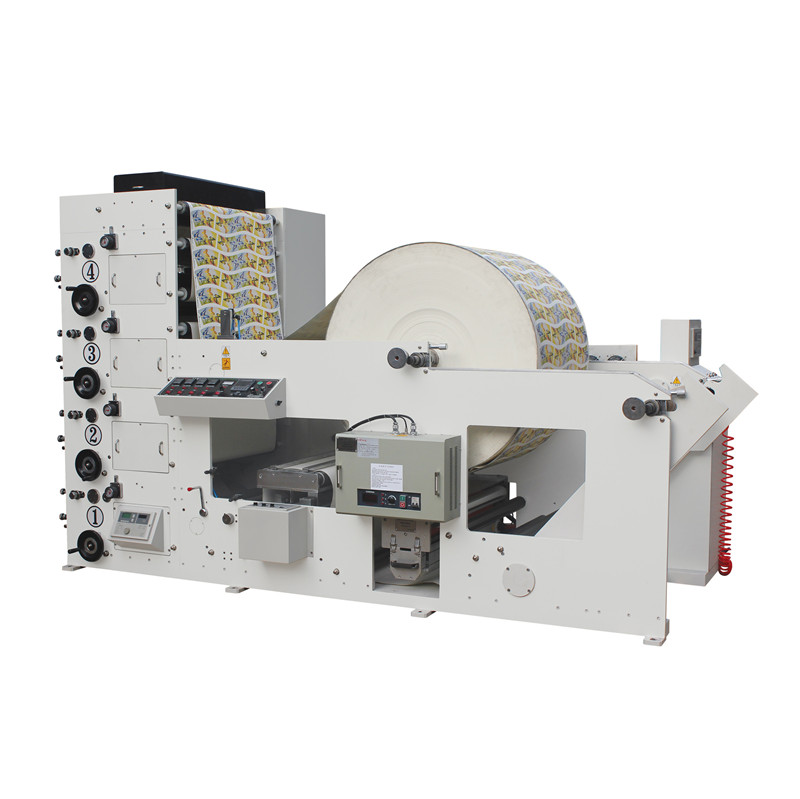

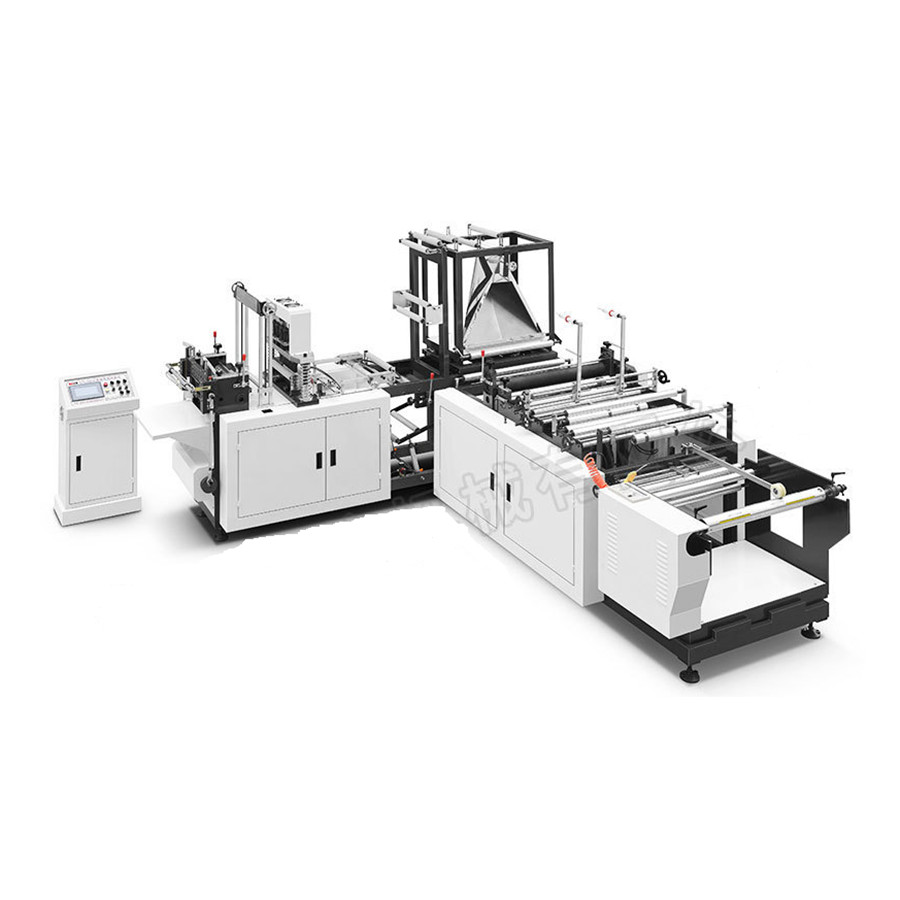

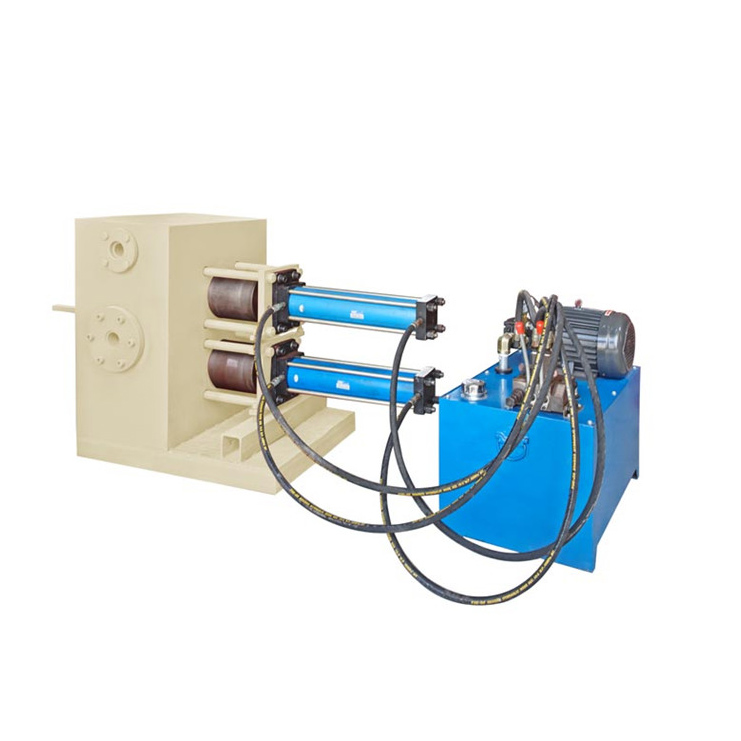

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for China High Quality Small Melt Blown Machine – S non woven fabric production line – MACHINERY , The product will supply to all over the world, such as: Brazil, Honduras, Amman, Our company has already had a lot of top factories and professional technology teams in China, offering the best products, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Write your message here and send it to us