China High Quality Second Hand Sanitary Napkins Production Line Suppliers – Auto Winged sanitary napkin Machine with quick-pack machine – MACHINERY

China High Quality Second Hand Sanitary Napkins Production Line Suppliers – Auto Winged sanitary napkin Machine with quick-pack machine – MACHINERY Detail:

Ⅲ.main point

1. Adapt PLC control the whole machine, operate the machine by touch screen

2. the conveyor belt can absorb the product, when it is run high speed, it will not fly

3. Cutter adapt pressure spring protect the knife from overload pressure

4. edge sealing ADL and cutter adapt the air cylinder protect the device

5. Main machine adapt frequency control the speed

6. main machine adapt bearing, timing belt, right angle gearbox, eruptional box drive

7. Cutter, ADL, edge sealing, easy quick package adapt carding strengthen by the drive

8. Universal coupling guarantee high speed drive is stable

9.Floor and wall made by 20mm steel plate, the base made by 120*120mm square steel pipe to guarantee the stable

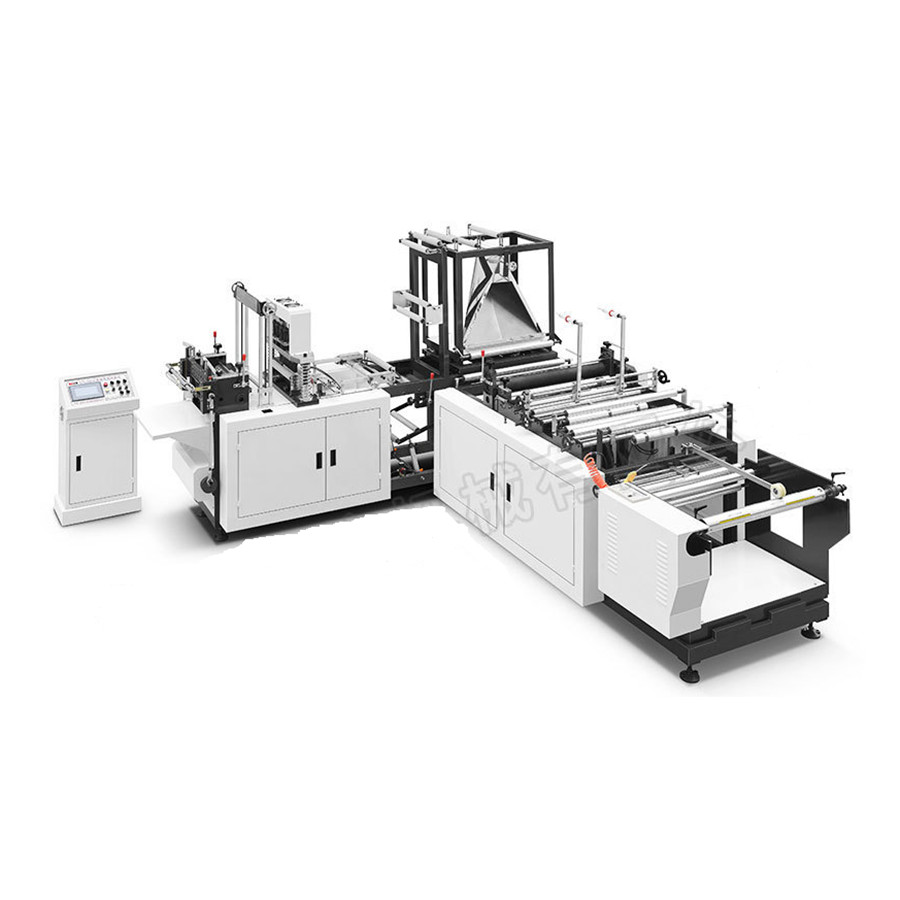

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for China High Quality Second Hand Sanitary Napkins Production Line Suppliers – Auto Winged sanitary napkin Machine with quick-pack machine – MACHINERY , The product will supply to all over the world, such as: Nigeria, Kazakhstan, UAE, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

Write your message here and send it to us