China High Quality Paper Plate Tray Dish Making Machine Suppliers – ML400Y Hydraulic Paper Plate Making Machine – MACHINERY

China High Quality Paper Plate Tray Dish Making Machine Suppliers – ML400Y Hydraulic Paper Plate Making Machine – MACHINERY Detail:

Technical Parameter

| Model | ML400Y |

| Paper Plate Size | 4-11inches |

| Paper Bowl Size | depth≤55mm;diameter≤300mm(raw material size unfold) |

| Capacity | 50-75Pcs/min |

| Power Requirements | 380V 50HZ |

| Total Power | 5KW |

| Weight | 800Kg |

| Specifications | 1800×1200×1700mm |

| Raw Material | 160-1000g/m2(original paper, white paperboard, whitecardboard, aluminum foil paper or others) |

| Air Source | Working pressure0.5Mpa Working air volume 0.5m3/min |

Samples

Product detail pictures:

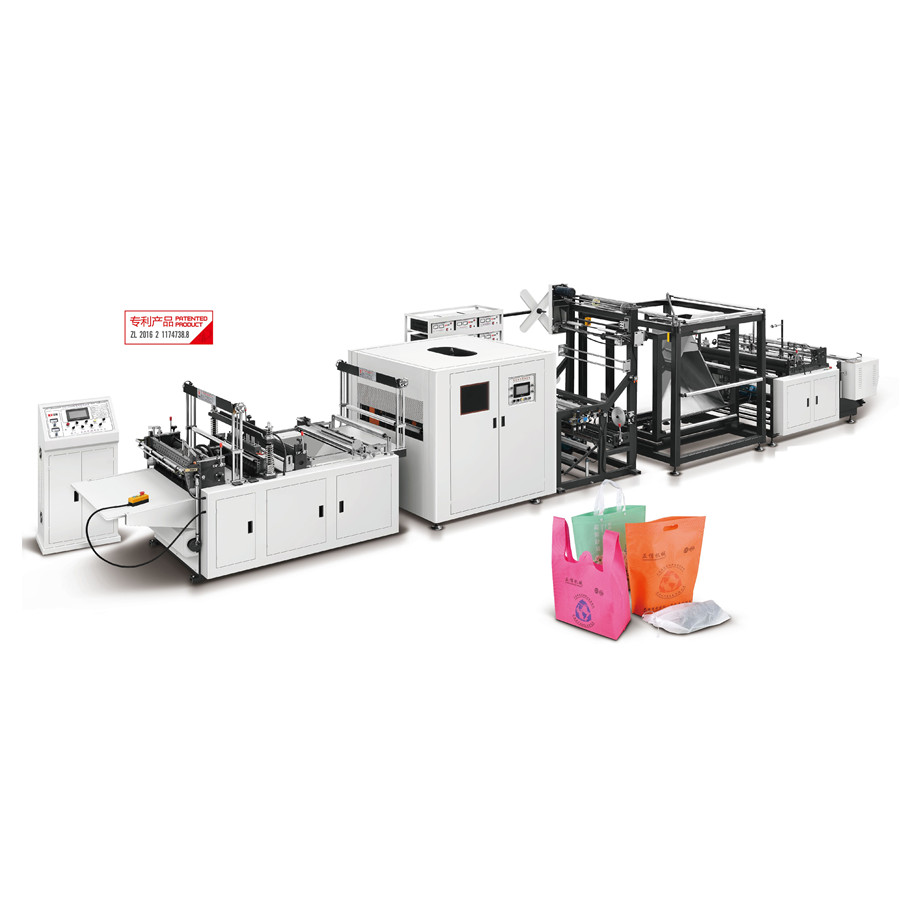

Related Product Guide:

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We're on the lookout forward for your stop by for joint growth for China High Quality Paper Plate Tray Dish Making Machine Suppliers – ML400Y Hydraulic Paper Plate Making Machine – MACHINERY , The product will supply to all over the world, such as: Tunisia, Brunei, Cairo, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.

Write your message here and send it to us