China High Quality Paper Plate Forming Machine Manufacturer – ML600Y Hydraulic Paper Plate Making Machine – MACHINERY

China High Quality Paper Plate Forming Machine Manufacturer – ML600Y Hydraulic Paper Plate Making Machine – MACHINERY Detail:

Technical Parameter

|

Main Technical Parameters |

|

|

Paper Plate Size |

4-13” |

|

Paper Grams |

100-800g/m2 |

|

Paper Materials |

Base paper, whiteboard paper, white cardboard, aluminum foil paper or others |

|

Capacity |

Double Stations 40-110pcs/min |

|

Power Requirements |

380V 50HZ |

|

Total Power |

8KW |

|

Weight |

1600kg |

|

Specifications |

3700×1200×1900mm |

|

Air Supply Requirement |

0.4Mpa, 0.3cube/min |

|

Other Notes |

Customize |

|

Oil Cylinder |

ML-63-150-5T-X |

|

Cylinder Stroke |

150mm |

independent research and development, the latest products, using the fast oil pressure system, each station is 15 – 20 minutes faster than ordinary machine

2.can be directly with the packaging machine (paper disc packaging labeling machine (film), good packaging and labeling). Suitable for production.

3.can automatically produce all kinds of non-standard products, finished product rate of one hundred percent, solved the problem of ordinary machines can not complete

4.hydraulic oil recycling, reduce emission pollution, low noise.

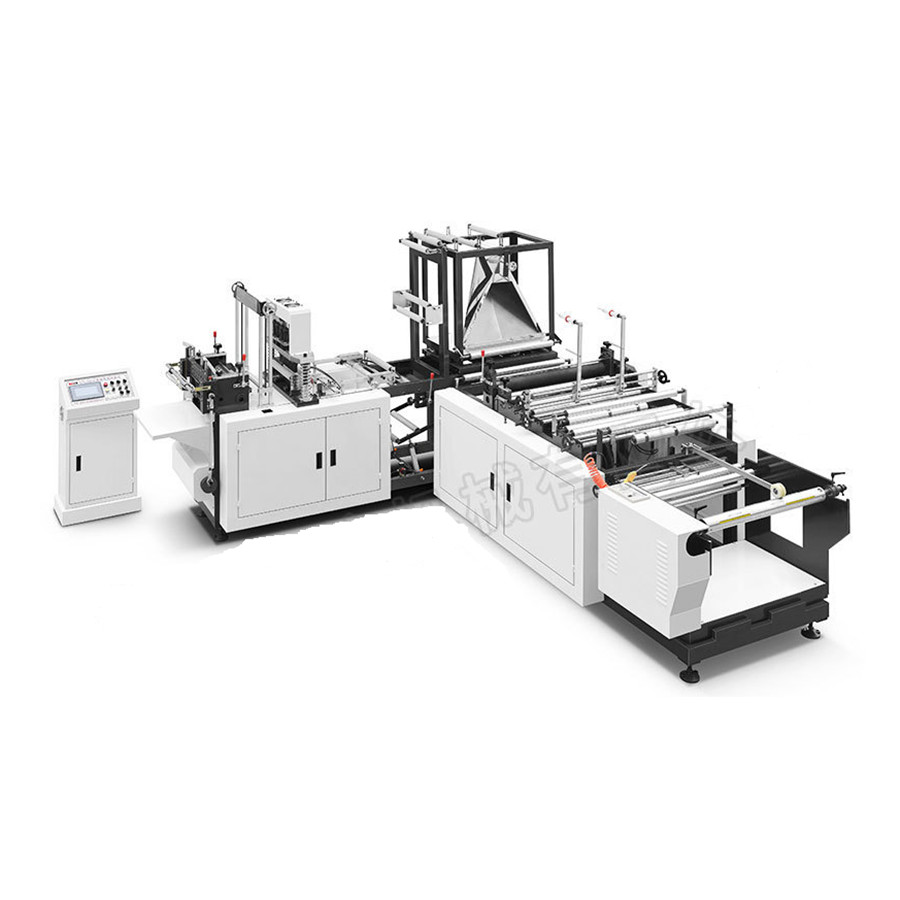

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for China High Quality Paper Plate Forming Machine Manufacturer – ML600Y Hydraulic Paper Plate Making Machine – MACHINERY , The product will supply to all over the world, such as: Hungary, Dubai, Mauritius, With nearly 30 years' experience in business, we are confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.