China High Quality Box Bag Making Machine Factory – FY-10E hot melt glue twisted paper handle making machine – MACHINERY

China High Quality Box Bag Making Machine Factory – FY-10E hot melt glue twisted paper handle making machine – MACHINERY Detail:

1. The machine is easy to operate and can produce paper handles with high speed usually reach 170 pairs per minute.

2. We design and offer the optional auto-production line, which can automatic gluing replace the human gluing procedure so that help to reduce lots of labor cost. It is strongly advice the paper bag producing factory use the auto-produce line that also support customize.

3. The unit paper bag can lift the heavy things of 15 kg at most, when the tension of raw materials reaches a certain level.

4. This machine adopts Huangshang melt-glue machine of Taiwan with service points in many countries, can provide customers with the fastest service.

Technical Data

|

Paper Roll Core Diameter |

Φ76 mm(3”) |

|

Max. Paper Roll Diameter |

Φ1000mm |

|

Production Speed |

10000pairs/hour |

|

Power Requirements |

380V |

|

Total Power |

7.8KW |

|

Total Weight |

Approx.1500kg |

|

Overall Dimension |

L4000*W1300*H1500mm |

|

Paper Length |

152-190mm(Optional) |

|

Paper Rope Handle Spacing |

75-95mm(Optional) |

|

Paper Width |

30/40mm |

|

Paper Rope Height |

100mm |

|

Paper Roll Diameter |

3.0-4mm |

|

Glue Type |

Hot-melt glue |

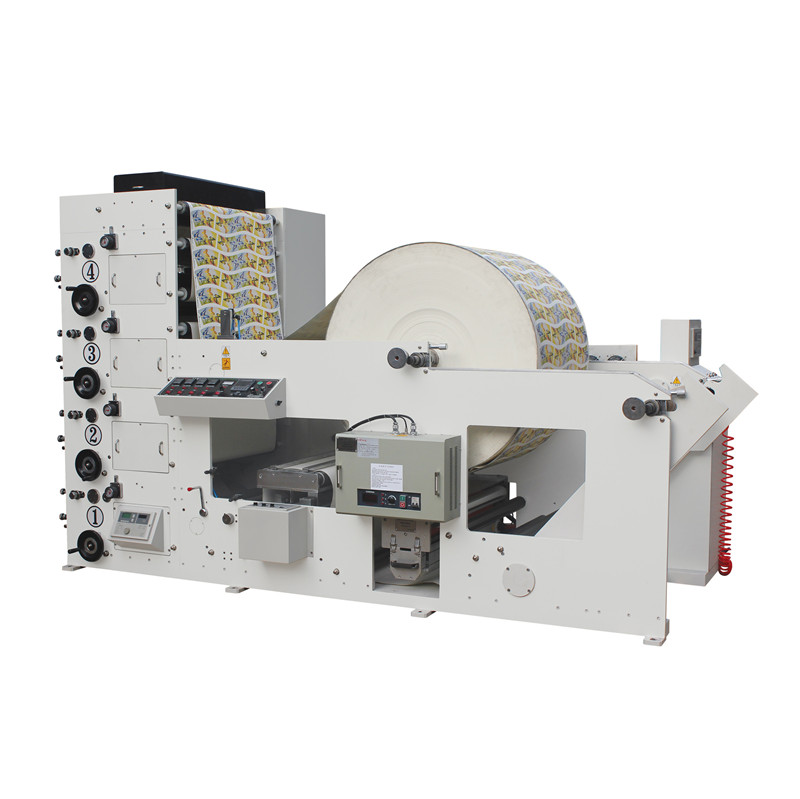

product picture

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for China High Quality Box Bag Making Machine Factory – FY-10E hot melt glue twisted paper handle making machine – MACHINERY , The product will supply to all over the world, such as: Russia, Germany, Bangkok, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!