Bedding Bag Machine Manufacturer – High speed square bottom paper bag machine – MACHINERY

Bedding Bag Machine Manufacturer – High speed square bottom paper bag machine – MACHINERY Detail:

main feature

1.Using Willon touch screen man-machine interface, the operation function is clear at a glance, easy to control

2.Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability

3.Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

4.The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

5. The raw material correction adopts servo motor to reduce the adjustment time of paper roll alignment.

| Model | XL-FD450 |

| Cutting Length | 270-530mm |

| Paper Bag Width | 210-450mm |

| Bottom width | 90-180mm |

| Paper bag thickness | 80-150g/㎡ |

| Mechanical speed | 30-220pcs/min |

| Paper bag speed | 30-150pcs/min |

| Paper roll width | 660-1290mm |

| Paper diameter | 1300mm |

| Inner diameter of paper | 76mm |

| Total power | 380V 3phase 4line 15kw |

| The whole machine pressure | 0.6MPa |

| Total Weight | 9000kg |

| Overall size | 10000*3800*2200mm |

flow chart

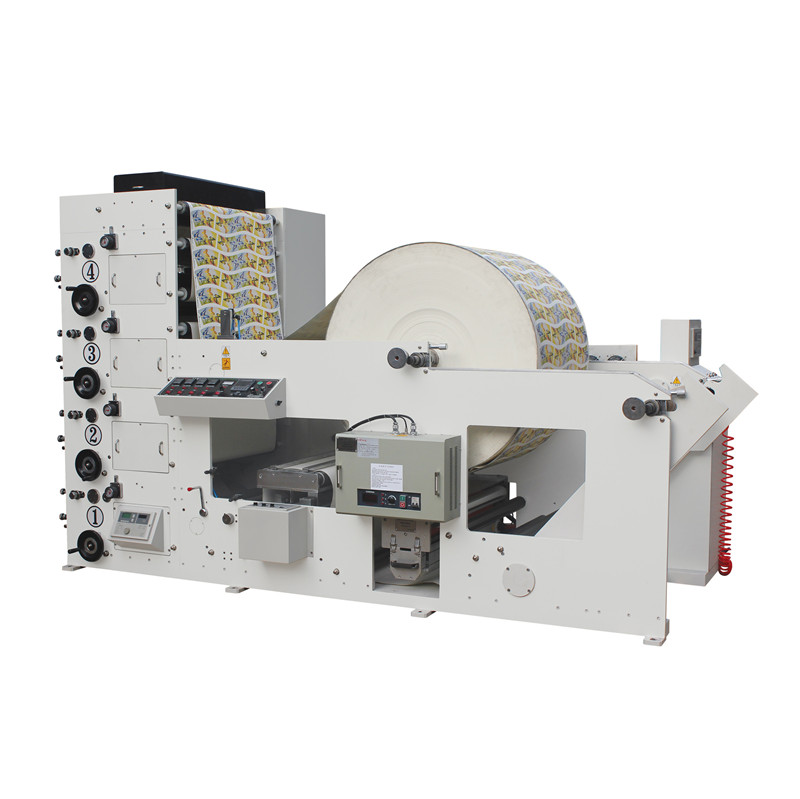

Product detail pictures:

Related Product Guide:

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for Bedding Bag Machine Manufacturer – High speed square bottom paper bag machine – MACHINERY , The product will supply to all over the world, such as: Italy, Morocco, Cannes, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!

Write your message here and send it to us